Increasing Productivity Doesn't Have to Mean an Increase in Labor

Midwest's newest robot cell increased customer production from 200 parts/hour to 465 parts/hour and reduced operators needed from 6 to just 2 per shift. Per day, our customer reduced 12 operators on this single cell.

That's a 200% increase in productivity and 66% decrease in manual labor needed. The numbers don't lie - talk about a ROI!

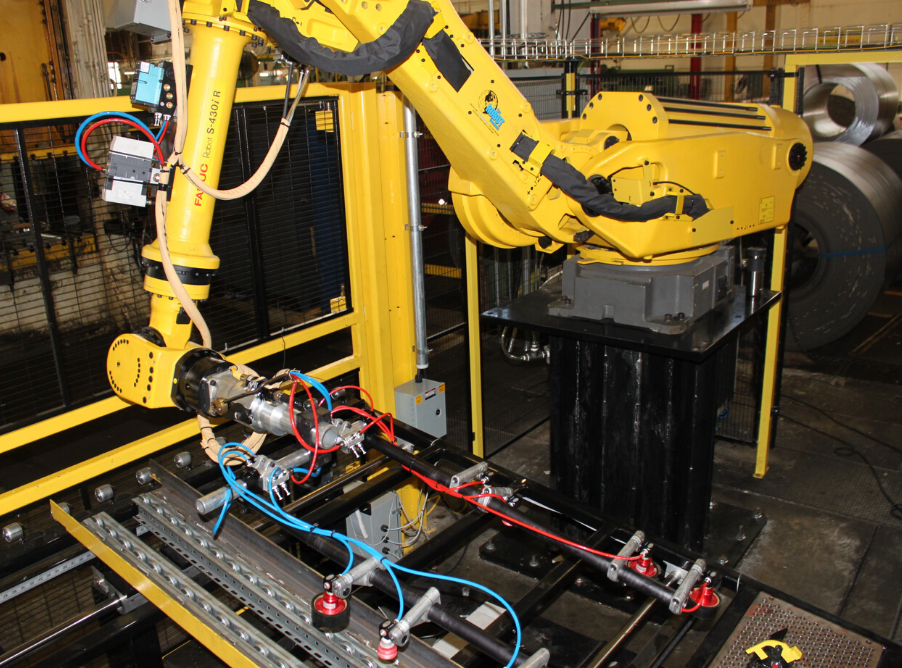

This robot cell is complete and in full swing. The cell was designed as a turn-key, two-robot pick and place. Our two robots load and unload a three-position progressive die which draws, trims, and restrikes the part.

This investment not only resulted in a drastic production increase, but through our onsite training, their plant floor team is now educated in a technical skill set that enhances their knowledge, demand, and competitive edge.

When integrating automation, Midwest Integration & Automation stresses the importance of safety, aims to drive significant ROI, and ensures facilitation and training on all of our implementations.

Want to automate your facility? Reach out for more information on how Midwest Integration & Automation can help.

This turn-key cell included:

- HMI/PLC Operator Stand – Allows operator to choose recipes and troubleshoot

- Safety Fencing, Controls, and Alarming – Designed to meet and exceed OSHA standards for years to come

- Skate Table – Midwest designed and fabricated; Operator sets blank to start process

- End Effectors – Midwest designed; Securely grabs part with aseries of air suction and magnets for part present

- Conveyance – Midwest designed; For unloading part from press

- Robot Programming, Wiring, and Pathing

- Remote Access to Cell – Due to the ability to remotely troubleshoot, there is no need to send a technician onsite

- Onsite Training – For smooth transitioning; Customer received technical instruction