Automation Making Manufacturing as Sweet as Sugar

McJak Candy Company was hand packaging their cotton candy, however, as a means to enhance productivity and increase the quality of their product, they partnered with Midwest Integration & Automation to automate the cotton candy cup loading process.

Quantity Control

With an automated system, the loading plunger creates a smooth end product and quantities are kept consistent as cups are filled to the exact level each time.

Reduced Human Contact

Food and beverage manufacturing companies go to extreme measures to make sure they are following and enforcing workplace safety and health standards. In today’s manufacturing environment, automation is a solution that promotes social distancing and reduces human error while complying with safety and health standards.

Enhanced Productivity and Efficiency

An automated process increases throughput and allows for a consistent volume of product to be filled into each cup. Additionally, operator errors are minimized and overall productivity is enhanced through the introduction of automation.

Pictured LEFT: Cotton candy cups before automating the packaging system.

Pictured RIGHT: Cotton candy cups after automating packaging.

The after photos show a more uniform end product, a reduction of empty space left in the cup, and an overall appealing product appearance that will remain consistent through this automated packaging process.

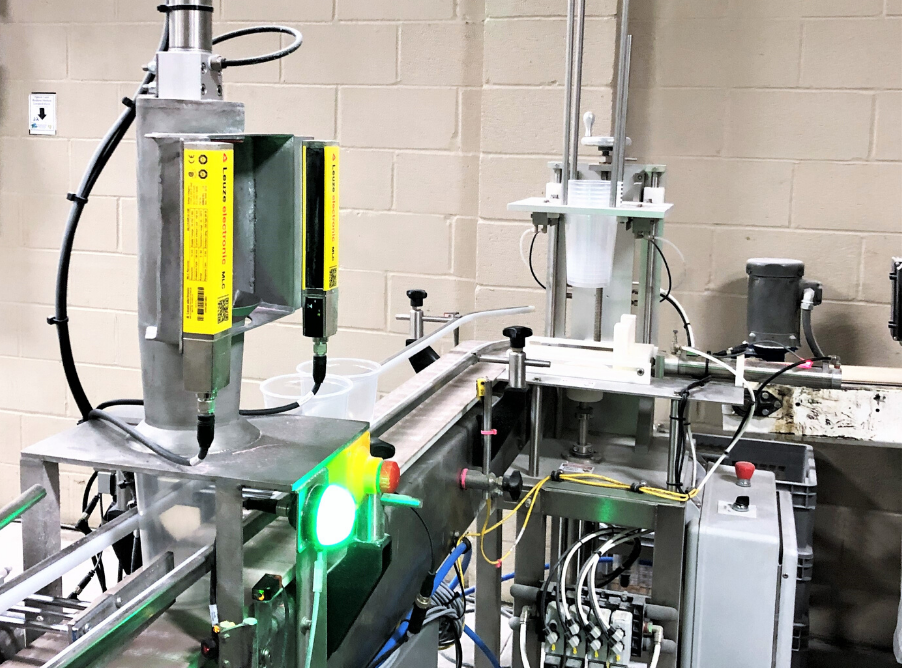

Listed below are key parts of the operating when automating:

- (1.) Pneumatic cylinders act as gates across the conveyor belt.

- (2.) Leuze sensors segment the cups forward.

- (3.) Operator feeds cotton candy into the chute as empty cup travels down conveyance and stops under the chute.

- (4.) Actuation from operator allows main loading plunger pushes the cotton candy into the cup.

- (5.) Gate opens and filled cup moves to next station.

This turn-key project included:

- Leuze Safety Sensors

- Leuze Light Curtains

- Bimba Cylinder

- Banner Actuating Button

- Horner XL4 PLC

Who knows, maybe these Midwest robots will be serving you cotton candy next time you go to your local county fair!