Midwest Integration & Automation offers "turn-key" solutions, from start to finish. With our engineers on staff, we provide programming, design, and fabrication in order to produce finished solutions. Our determination to deliver high quality products and services comes from our knowledgeable staff and our dedication to our customers and their projects.

Our Panel Shop, Robotic Integration division, Applied Services division, and our Machine Shop allow us to provide a full range of services. Our hands-on approach, allows us to get solutions to market faster, ensure satisfaction, and deliver what we strive to provide for our customers.

We provide ...

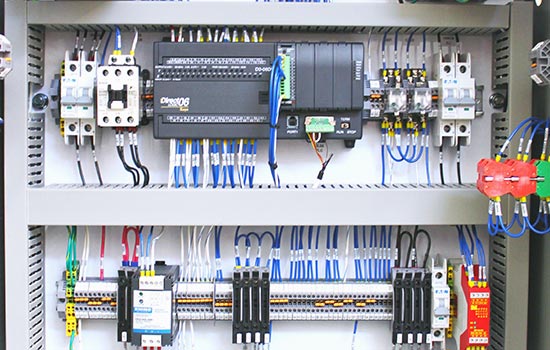

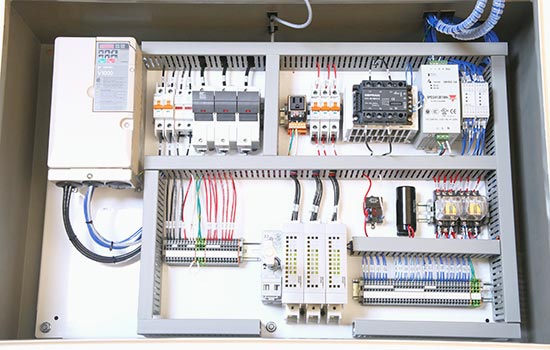

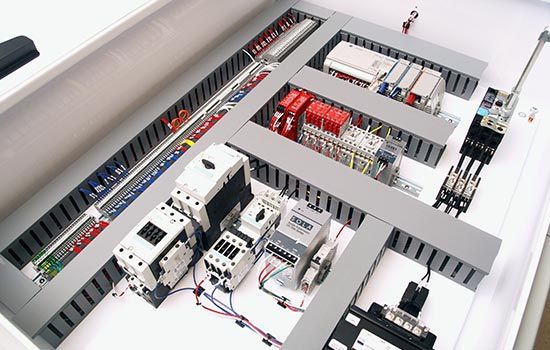

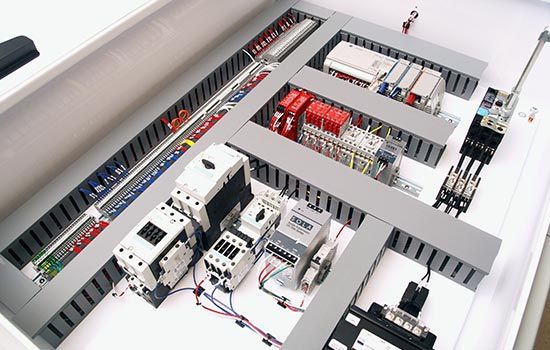

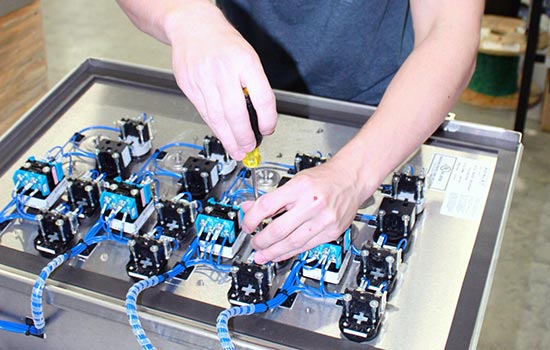

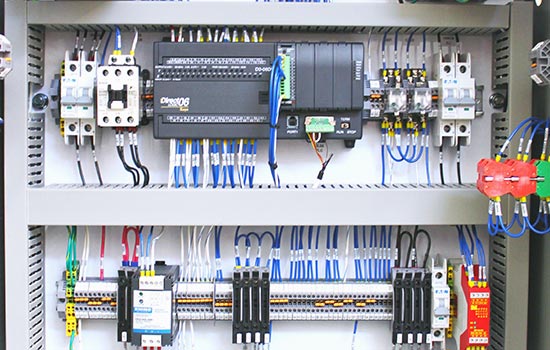

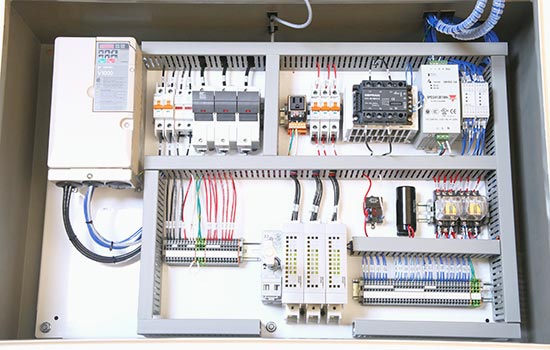

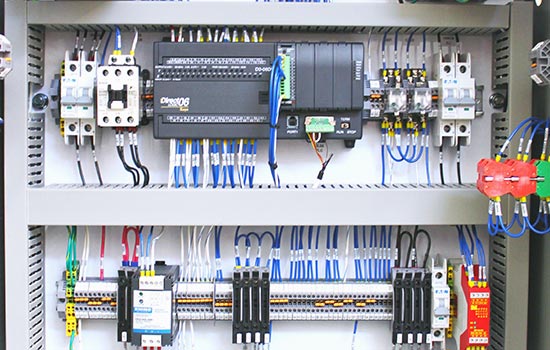

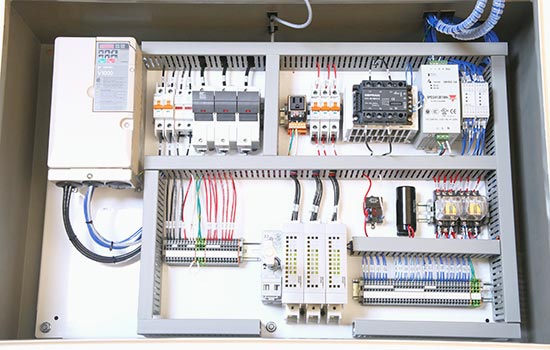

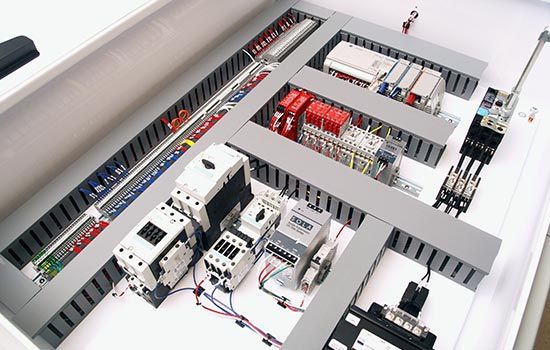

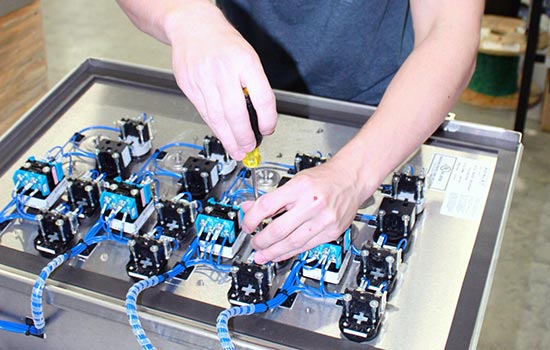

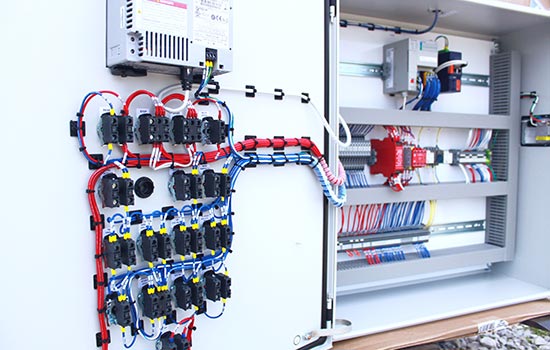

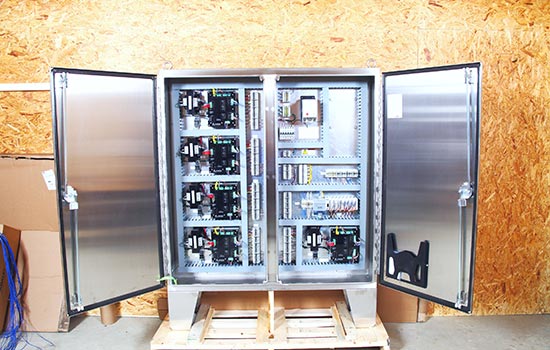

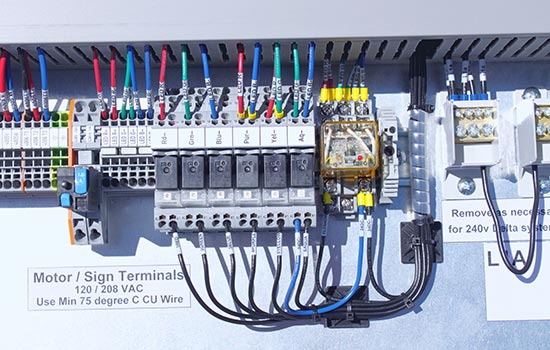

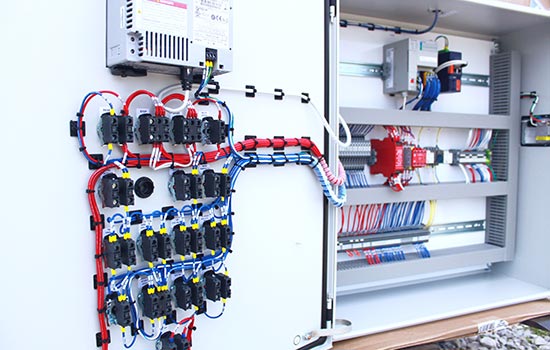

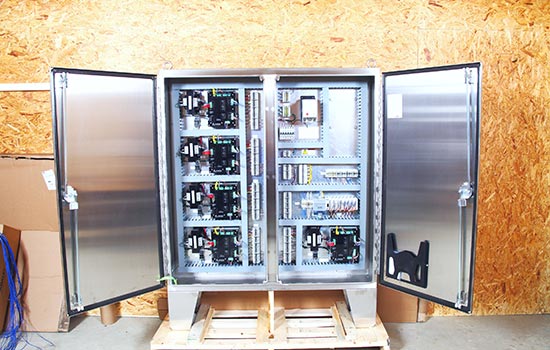

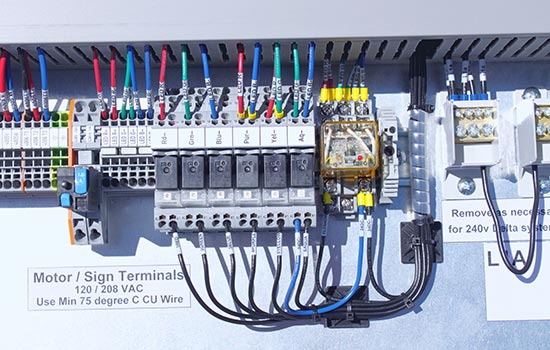

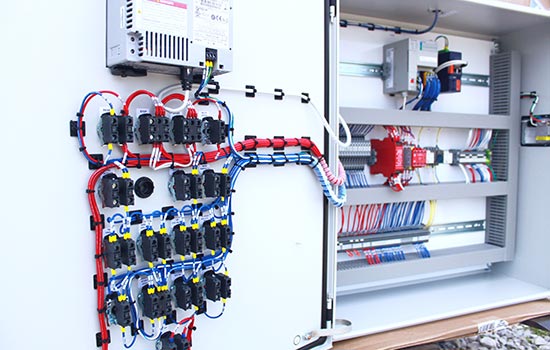

Panel Shop

Midwest Integration & Automation works hard to provide solutions that add value to our customers. This simple concept has blossomed into a business unit that supplies custom solutions:

Consultation

Our experienced sales engineers know the right questions to ask to not only get the job done, but to get the job done right. Midwest Integration and Automation, Inc takes the time to understand their products and their customers fully so they are in the best position to propose solutions.

Design

Our design process at Midwest Integration and Automation, Inc possesses a natural advantage -- the products we integrate are also products that we distribute on site. This allows us to pull stock and design in our shop, and additionally, provides a simple way to document proof of concept through photographing or videoing solutions found during this step.

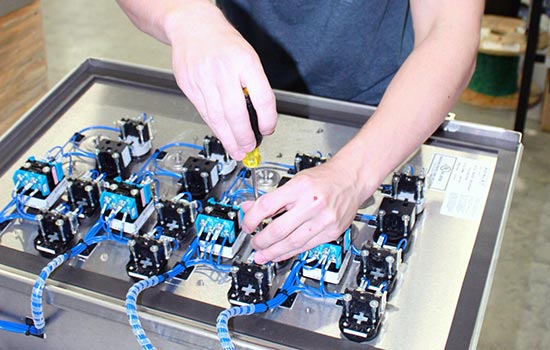

Buildout

During the process of a panel build or an integration job, our personnel utilizes today's technology to update our customers directly through photos or videos. Time is integrated into this step to allow customers an opportunity to review as well as present feedback regarding the progress of the job. This concept includes the customer in the process, saves time, and ensures expectation upon delivery.

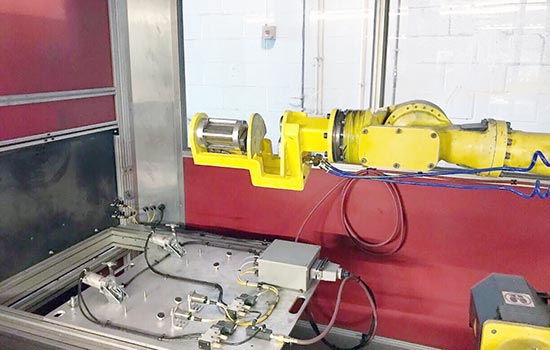

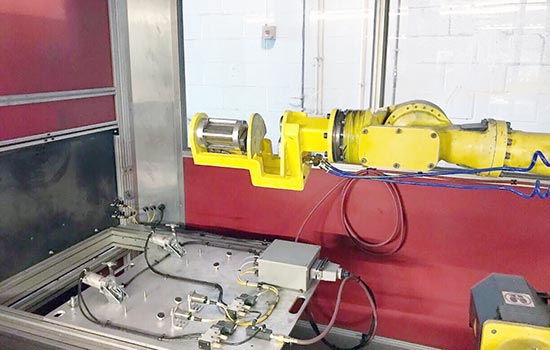

Robot Integration

Whether you have a new robot or an old one, Midwest Integration & Automation, Inc has the ability to program as well as install them in your facility. While exceeding current safety standards, we ensure your cell will be compliant for many years.

Our background includes:

Applied Services

Midwest's expanding Applied Services department specializes in quoting, designing, building, programming and integrating turnkey industrial systems. With over 25 years of automation experience, there are few machines or industrial processes our engineers have not seen.

Our recent projects include:

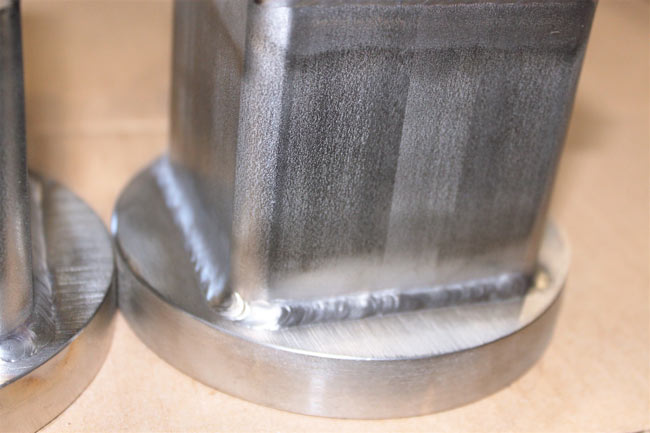

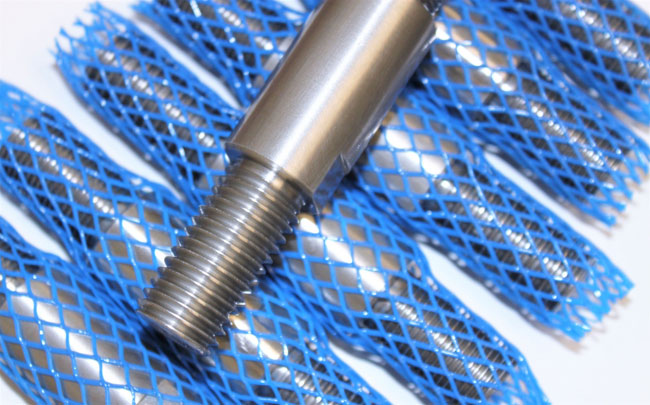

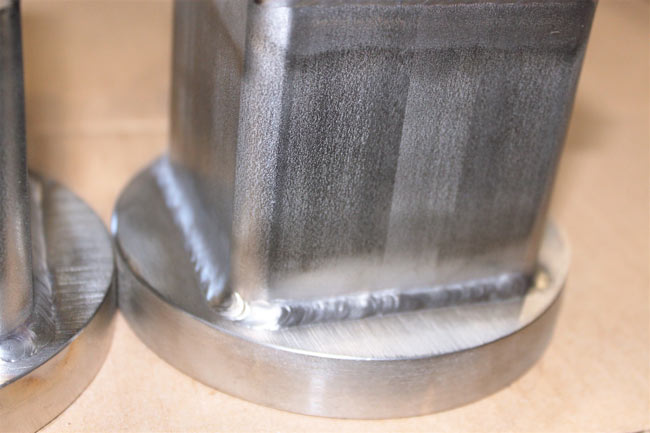

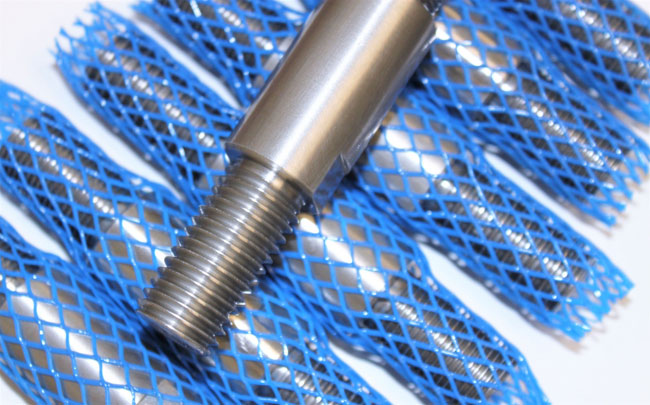

Machine Shop

Maca Mold & Machine is Midwest Integration and Automation, Inc’s machine shop. Maca has been in business for over 80 years and through the collaboration between companies, Midwest’s capabilities have greatly expanded. The addition has allowed us to provide an array of machining services. We approach each project with quality, care, and creativity and all of the above are supported by the machining experience of our team at Maca.

- Complex Assembly

- Custom Assembly

- Welding

- Prototyping

- 3D Machining

- Product Prototyping

- Jig & Fixtures for Welding

- Mig, Tig, or Spot Welding

- Sheet Metal Bending, Forming, and Welding

- Extrusion/Stamping Dies and Components

- Full Prototyping

- CNC Milling

- CNC Turning

- CNC Grinding

- Automotive

- Automation & Controls

- Discrete Manufacturing

- Food and Beverage

- Marine

- Medical

- Oil and Gas

- Waste Water